The turbocharger system enhances engine performance by forcing more air into combustion chambers, increasing compression ratios and thermal energy release during combustion. This technology allows for higher power and torque output while maintaining efficiency. Unlike superchargers, turbochargers utilize exhaust gas flow to spin turbines, enabling smoother power band transitions. Supported by high-performance air filters and efficient exhaust systems, turbocharged engines deliver robust performance and improved fuel economy through optimized cylinder pressure.

The turbocharger system has emerged as a pivotal component in modern engines, significantly impacting both cylinder pressure and overall engine load. This article delves into the intricate relationship between these factors, exploring how turbochargers enhance performance. We’ll break down the mechanisms behind increased cylinder pressure, its advantages in boosting power and efficiency, and the role of turbochargers in managing varying load demands for optimized torque output. Additionally, we’ll provide technical insights into turbocharger system operation and recent advancements that further revolutionize engine performance.

- The Role of Turbocharger System in Enhancing Cylinder Pressure

- – Explanation of cylinder pressure and its significance in engine performance

- – How turbochargers increase air/fuel mixture pressure

The Role of Turbocharger System in Enhancing Cylinder Pressure

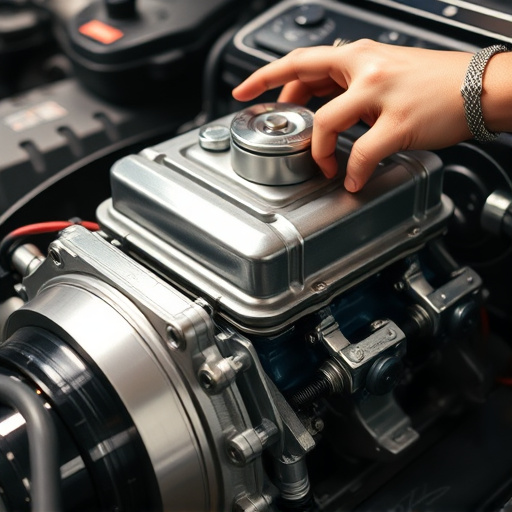

The turbocharger system plays a pivotal role in enhancing cylinder pressure, thereby boosting the overall performance of an engine. By forcing more air into the combustion chamber than what would be possible under normal atmospheric conditions, it increases the available fuel-air mixture for each burn cycle. This results in higher compression ratios and, consequently, greater thermal energy release during combustion. The forced induction provided by a turbocharger system allows engines to produce more power and torque while maintaining efficiency.

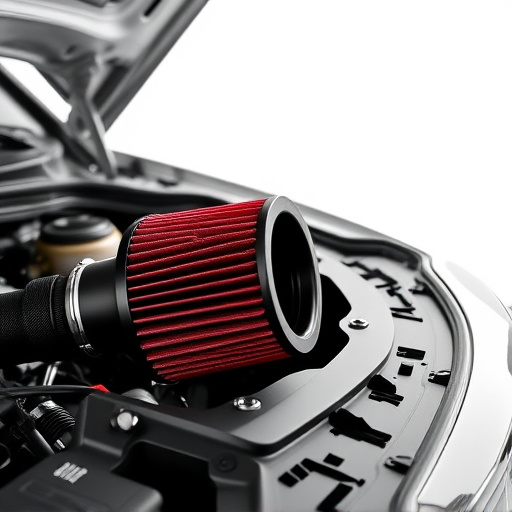

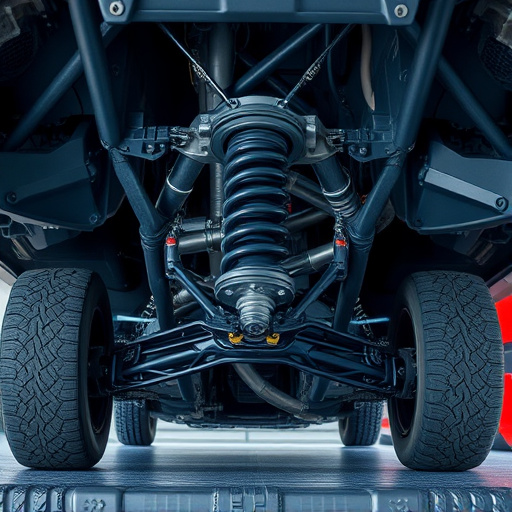

This advanced technology also facilitates smoother transitions between power bands, leading to improved drivability. Unlike superchargers, which rely on engine belt drive or mechanical force, turbochargers utilize exhaust gas flow to spin their turbines. This not only enhances cylinder pressure but also contributes to a more seamless power delivery. Additionally, the integration of high-performance air filters and efficient exhaust systems, such as cat-back exhausts, further optimizes air intake and waste gas removal, complementing the turbocharger system for optimal engine performance.

– Explanation of cylinder pressure and its significance in engine performance

Cylinder pressure plays a pivotal role in determining the overall performance of an engine. It refers to the internal force generated within each cylinder during combustion, which directly impacts the power and efficiency of the vehicle. When a turbocharger system is integrated into an engine, it significantly influences cylinder pressure. This advanced technology forces more air into the cylinders, enhancing the combustion process and thereby increasing the pressure. As a result, the engine can produce more power, leading to improved vehicle performance.

The impact of higher cylinder pressure extends beyond power output. It also contributes to better fuel efficiency as the optimized air-fuel mixture ensures more effective burning. Moreover, with the right combination of turbocharger settings and tuning, performance exhaust systems and even high-performance air filter kits can further enhance this effect, making for a robust and responsive engine that delivers both power and economy.

– How turbochargers increase air/fuel mixture pressure

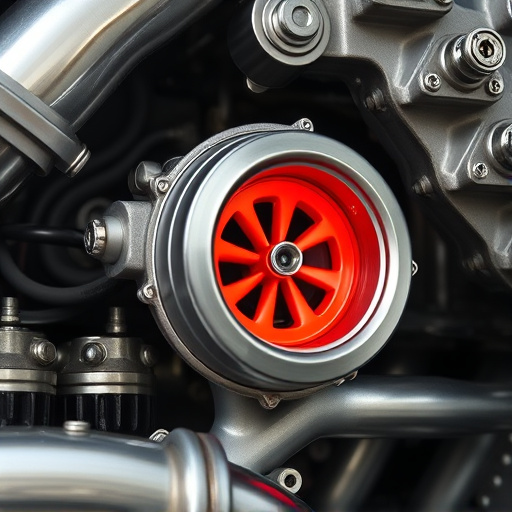

Turbochargers significantly enhance the pressure of the air-fuel mixture within an engine’s cylinders, leading to improved performance and efficiency. This is primarily achieved through their unique design, which leverages exhaust gas energy. As exhaust gases leave the combustion chamber, they pass through a turbine in the turbocharger, causing it to spin at high speeds. Connected by a shaft to a compressor, this rotation increases air pressure in the intake system. The result is a denser air-fuel mix entering the cylinders, allowing for more powerful and efficient burning of fuel.

This increased cylinder pressure is particularly beneficial in various driving conditions. For instance, during acceleration, the turbocharger swiftly delivers extra air, enhancing torque output. Moreover, it improves overall engine load capacity, making the vehicle responsive and capable of handling demanding tasks. Additionally, many modern vehicles equipped with turbochargers incorporate advanced systems like cold air intakes and optimized brake components to further enhance performance and ensure smooth operation.

The turbocharger system plays a pivotal role in enhancing cylinder pressure, thereby significantly improving engine performance. By compressing and delivering more air, turbochargers increase the air-fuel mixture pressure, leading to better combustion and higher torque output. This boost in pressure not only enhances fuel efficiency but also enables engines to handle heavier loads with reduced strain. Understanding how turbocharger systems impact cylinder pressure is crucial for optimizing engine performance and ensuring efficient, powerful operation.