A turbocharger system significantly enhances internal combustion engine performance through forced induction, boosting fuel combustion and power output. Key components include a turbine (powered by exhaust gases), a compressor (drawing in and compressing ambient air), and an intercooler. These systems offer seamless power delivery, durability, instant response, and long-term performance stability, reducing maintenance costs and eliminating frequent replacements. In the automotive industry, reliable turbocharger systems are advantageous for high-performance vehicles, ensuring optimal responsiveness and minimizing system failure risks. Advanced materials, robust construction, sealing mechanisms, and efficient exhaust systems contribute to their longevity.

Discover the power of reliable turbocharger systems, essential for sustained high-performance vehicles. This article explores the intricate world of these forced induction systems, delving into their benefits and key components for long-term durability.

From understanding the fundamentals to identifying critical design considerations, we uncover why turbochargers are evolving as a game-changer in automotive engineering. Uncover the secrets to harnessing reliable power for the modern vehicle’s engine.

- Understanding Turbocharger Systems: An Overview

- The Benefits of Long-Term Reliability in Turbochargers

- Key Components and Design Considerations for Durable Turbocharger Systems

Understanding Turbocharger Systems: An Overview

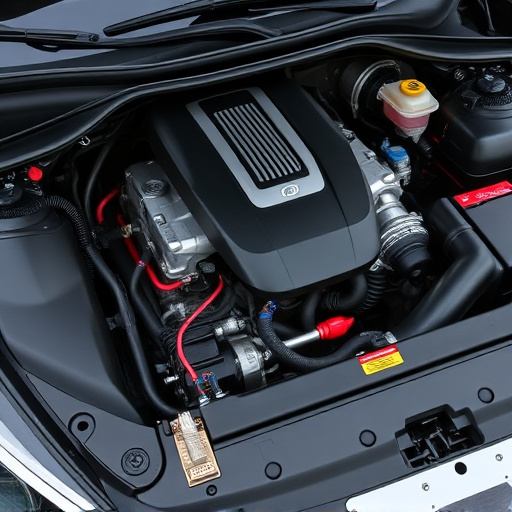

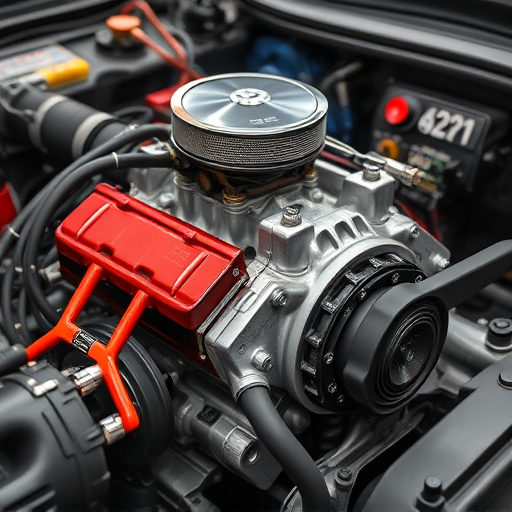

A turbocharger system is a powerful component that enhances an internal combustion engine’s performance by forcing more air into the engine during each intake cycle. This process, known as forced induction, allows for increased fuel combustion and, consequently, more power output. The primary advantage lies in its ability to provide a boost in horsepower while maintaining reliability, making it especially appealing for long-term use.

These systems consist of several key parts, including a turbine, compressor, and an exhaust gas flow path. The turbine spins from the engine’s exhaust gases, driving the compressor, which draws in ambient air and compresses it before delivering it to the engine. This process significantly increases the amount of oxygen available for combustion, resulting in improved engine efficiency and performance. Unlike some alternatives, turbochargers offer a seamless power delivery, ensuring that drivers experience instant response without compromising durability, especially when paired with high-quality suspension components and a cat back exhaust system or even more advanced suspension kits.

The Benefits of Long-Term Reliability in Turbochargers

In the automotive industry, a turbocharger system that offers long-term reliability is an asset worth celebrating. The benefits extend far beyond simply ensuring a vehicle’s engine maintains its power over time; it also guarantees consistency in performance. This is particularly crucial for high-performance cars where drivers demand peak efficiency and responsiveness, especially during extended use. A reliable turbocharger means that the vehicle’s performance brakes won’t be compromised due to system failure or degradation.

Moreover, long-term reliability reduces the need for frequent replacements or repairs, which can be costly. It also lowers maintenance costs over the car’s lifespan, allowing owners to focus more on enjoying their driving experience with enhanced air intake systems, rather than worrying about technical issues. This longevity is a game-changer for both automotive enthusiasts and manufacturers alike, ensuring that high-performance parts can deliver on their promise without compromising reliability.

Key Components and Design Considerations for Durable Turbocharger Systems

A durable turbocharger system is a complex assembly of components designed to withstand prolonged use while maintaining peak performance. Key components include the turbine, compressor, and the intercooler, each playing a critical role in the charge and exhaust cycles. The turbine, placed in the exhaust stream, harnesses energy from escaping gases to spin the compressor, which draws in cold air through a high-flow performance air filter. This efficient air intake ensures maximum compression ratio, enhancing engine power output.

Design considerations for long-term reliability focus on material strength and endurance. High-quality alloys and robust construction prevent premature wear and tear, ensuring the turbocharger maintains its efficiency over time. Additionally, advanced sealing mechanisms guard against leakages, which can cause significant performance losses. Efficient exhaust mufflers and exhaust tips, while reducing noise pollution, also play a role in maintaining optimal pressure differentials within the system for smoother operation.

In conclusion, a well-designed and reliable turbocharger system is essential for sustained high performance. By understanding the key components and focusing on long-term reliability, manufacturers can create efficient, durable systems that power vehicles for years to come. This article has explored the benefits of such systems, highlighting their crucial role in modern automotive engineering.