Heat soak in turbocharger systems, caused by excess engine heat buildup, can severely damage components and reduce performance. High-performance vehicles are more susceptible due to increased turbo strain. Solutions include robust cooling systems, optimized airflow, high-flow cat-back exhausts, efficient coolant management, and strategic component placement. Regular maintenance, upgrades, and proper integration with the vehicle's cooling system are vital to prevent heat soak, ensuring optimal turbocharger performance and longevity.

In the high-performance realm of turbocharger systems, heat soak can be a game changer, reducing efficiency and potentially causing damage. This article delves into the science behind heat soak in turbochargers and offers practical solutions for its prevention. By understanding key factors contributing to this issue, such as ambient temperature and exhaust gas flow, you’ll gain insights into implementing effective coolant management strategies. Discover expert tips to keep your turbocharger system running cool and efficient.

- Understanding Heat Soak in Turbocharger Systems

- Key Factors to Prevent Heat Soak

- Implementing Effective Strategies for Coolant Management

Understanding Heat Soak in Turbocharger Systems

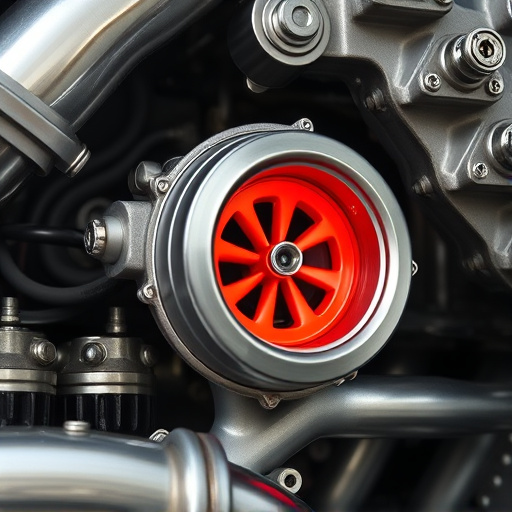

Heat soak is a common issue in turbocharger systems, leading to performance degradation and potential damage if left unaddressed. It occurs when excess heat from the engine’s combustion chamber accumulates within the turbocharger, causing its components to overheat. This phenomenon is particularly prevalent in high-performance vehicles or those with heavy workloads, where the turbocharger works overtime to maintain boost pressure. Understanding heat soak involves recognizing that it’s not just about elevated temperatures; it’s about managing heat transfer and ensuring a balanced flow of cool air within the system.

The effects of heat soak extend beyond the turbocharger itself, impacting other critical engine components such as brake and suspension systems. Over time, prolonged exposure to high temperatures can cause these parts to wear out faster, leading to reduced vehicle performance and safety concerns. A well-designed turbocharger setup considers not only boosting efficiency but also efficient cooling strategies. Incorporating a robust cooling system and ensuring proper airflow through the engine bay, often facilitated by a high-flow cat-back exhaust system, are key steps in mitigating heat soak.

Key Factors to Prevent Heat Soak

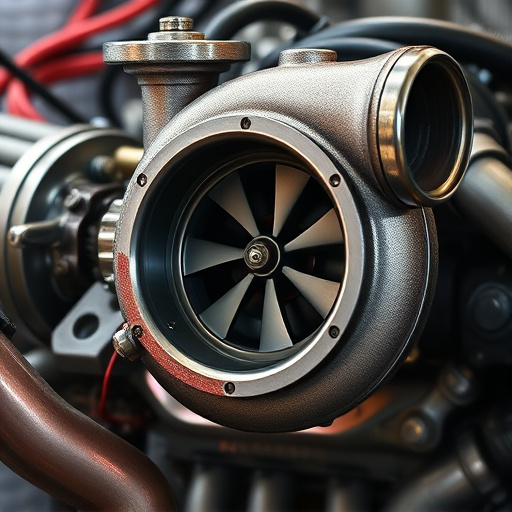

Preventing heat soak in a turbocharger system setup is paramount for maintaining optimal performance and longevity. Key factors to consider include efficient cooling solutions such as enhanced oil cooling systems, robust intercooler designs that facilitate quick air dispersion, and strategic placement of components to minimize heat concentration. Upgrading to high-performance suspension kits can aid in managing heat transfer by allowing for better vehicle dynamics and improved airflow around crucial parts.

Additionally, ensuring top-tier brake components is essential, as their efficient operation reduces overall system stress, thereby indirectly mitigating heat soak. Modifying the exhaust system with a cat back exhaust kit not only enhances performance but also contributes to better engine cooling by reducing backpressure and facilitating faster gas expulsion, which in turn decreases internal component temperatures.

Implementing Effective Strategies for Coolant Management

Implementing effective strategies for coolant management is a critical aspect of preventing heat soak in a turbocharger system setup. Ensuring optimal coolant flow through the charger and its components is key. This involves regular checks and maintenance to prevent any obstructions in the coolant path, such as clogged filters or leaks within the air intake systems, which can hinder efficient cooling.

Additionally, managing the overall temperature of the turbocharger system requires integration with the vehicle’s existing cooling system, especially considering the impact of high-performance exhaust systems. By monitoring and regulating coolant temperatures, you minimize the risk of heat soak, ensuring the turbocharger operates within its specified temperature range for peak performance and longevity.

Preventing heat soak in a turbocharger system is vital for maintaining optimal performance and efficiency. By understanding the causes, such as inadequate coolant flow or high ambient temperatures, and implementing strategies like improving air flow, using efficient coolants, and regular maintenance, you can significantly reduce heat soak issues. These measures ensure your turbocharger system operates at its best, enhancing overall engine power and fuel economy in various driving conditions.