Monitoring and maintaining boost pressure in a turbocharger system is crucial for optimal performance, reliability, and fuel efficiency. High-quality sensors and diagnostic software offer real-time data insights, helping to identify issues like leaks or turbine wear. Regular maintenance, including filter checks and unrelated component inspections, ensures peak efficiency and preserves vehicle performance, allowing users to customize their turbocharger system for enhanced driving experience.

Monitoring boost pressure in a turbocharger system is paramount for maintaining optimal performance. This article guides you through the process, starting with understanding boost pressure dynamics within turbocharger systems. We’ll explore essential tools and techniques for accurate monitoring, and provide insights on interpreting data to ensure peak efficiency. By following these practices, you can enhance your turbocharger system’s reliability and power output.

- Understanding Boost Pressure in Turbocharger Systems

- Tools and Techniques for Monitoring Boost Pressure

- Interpreting Data and Maintaining Optimal Performance

Understanding Boost Pressure in Turbocharger Systems

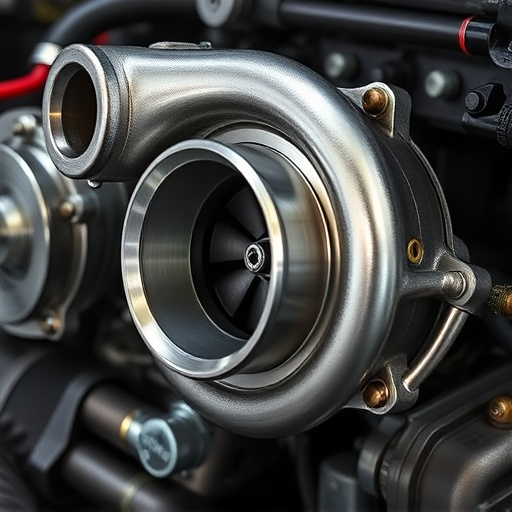

Boost pressure is a critical parameter in any turbocharger system, directly influencing engine performance and efficiency. It refers to the additional pressure generated by the turbine as exhaust gases pass through it, driving the compressor to draw in and compress intake air. This compressed air then mixes with fuel for combustion, resulting in increased power output. Understanding boost pressure is crucial for optimizing both the engine’s performance and its overall efficiency.

In a turbocharger system, boost pressure is regulated by various components, including the turbine, compressor, and wastegate. The exhaust systems play a vital role in this process, providing the energy that spins the turbine. High-performance air filters can also enhance intake airflow, indirectly affecting boost pressure. Ensuring these components are well-maintained and aligned allows for precise control of boost pressure, which is essential for achieving optimal performance without compromising efficiency or safety, especially when considering performance brakes as part of the overall system dynamics.

Tools and Techniques for Monitoring Boost Pressure

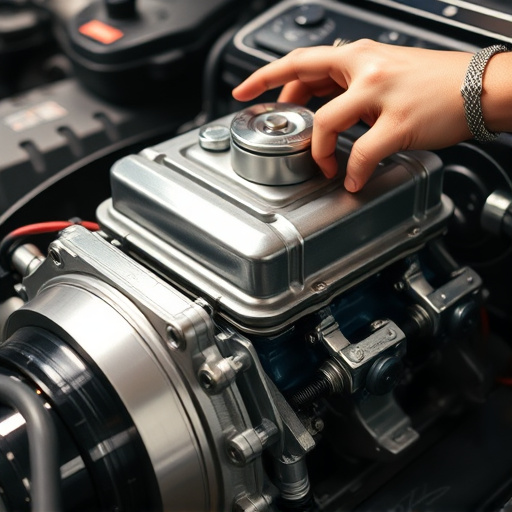

Monitoring boost pressure in a turbocharger system requires precise tools and techniques to ensure optimal performance and reliability. High-quality manometers and pressure sensors are essential for accurate readings, providing real-time data on the pressure within the system. These devices connect directly to the turbocharger’s outlet or inlet, allowing mechanics to easily track changes in boost pressure during operation. Additionally, advanced diagnostic software can interpret these sensor signals, offering valuable insights into engine performance and identifying potential issues with the turbocharger or exhaust systems.

Regular maintenance also involves inspecting critical components like the air filter kits for any debris buildup that could restrict airflow. Properly maintained air filters ensure optimal air-fuel mixture, which directly impacts boost pressure. Even seemingly unrelated parts, such as brake pads, can indirectly affect performance; worn brakes can cause vibrations and changes in exhaust gas flow, influencing turbocharger efficiency. By employing these tools and techniques, users can effectively monitor and optimize their turbocharger system’s boost pressure, leading to improved engine output and fuel efficiency.

Interpreting Data and Maintaining Optimal Performance

Monitoring boost pressure is crucial for maintaining optimal performance in a turbocharger system. The data gathered provides insights into how efficiently the turbo is boosting and can help identify issues early on. For instance, a sudden drop in boost pressure might indicate a leak in the system or wear and tear in the turbine. By analyzing these trends, users can make informed decisions to address potential problems before they affect overall vehicle performance. Regular checks ensure the turbocharger operates within its specified parameters, enhancing fuel efficiency and power output.

Additionally, understanding boost pressure dynamics allows for fine-tuning of various components, such as muffler tips or exhaust tips, to optimize gas flow. This customization not only enhances engine braking but also contributes to better control over the vehicle’s performance brakes. Ultimately, interpreting data accurately enables users to tailor their turbocharger system for maximum efficiency and enjoyment, making it a key aspect of any performance-oriented vehicle setup.

Monitoring boost pressure in a turbocharger system is essential for maintaining optimal performance and ensuring longevity. By understanding the dynamics of boost pressure, utilizing appropriate tools, and interpreting data accurately, vehicle mechanics can fine-tune their turbocharger systems for enhanced efficiency and power. Regular checks and adjustments ensure the turbocharger operates within its sweet spot, maximizing engine output while minimizing the risk of damage. This knowledge is pivotal in the ever-evolving world of automotive technology, where turbochargers continue to be game changers in enhancing vehicle performance.