The turbocharger system boosts vehicle performance by compressing air for efficient fuel burning, relying on components like turbines, compressors, intercoolers, sensors, and exhaust systems. Regular maintenance, including filter cleaning, exhaust care, oil level monitoring, and prompt leak repairs, is essential to prevent issues like leaks, sensor malfunctions, increased friction, overheating, and engine performance problems. Adhering to these practices extends the lifespan of the turbocharger system.

In today’s high-performance vehicles, the turbocharger system plays a crucial role in boosting engine power. However, like any complex mechanism, it’s prone to issues that can impact efficiency and reliability. This article delves into the basics of the turbocharger system, exploring its key components and functions. We then uncover common problems, from oil leaks to sensor malfunctions, offering practical preventive measures for maintaining optimal performance. By understanding these aspects, folks can ensure their turbocharger systems operate smoothly, enhancing overall vehicle health.

- Understanding Turbocharger System Basics: Key Components and Functions

- Common Issues: From Oil Leaks to Sensor Malfunctions

- Preventive Measures: Maintenance Tips for Reliable Performance

Understanding Turbocharger System Basics: Key Components and Functions

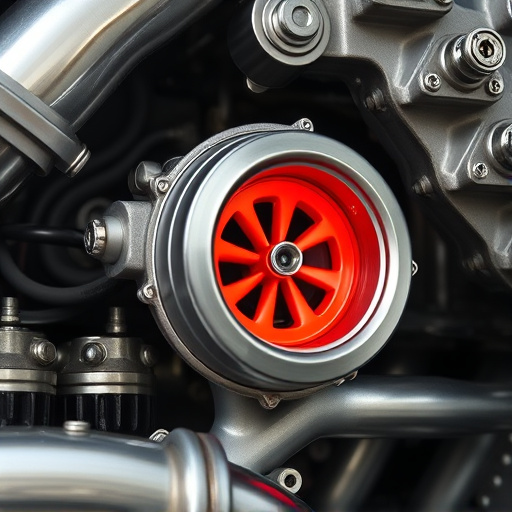

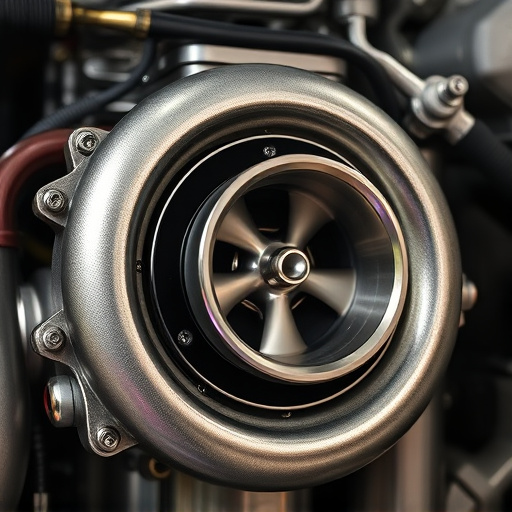

A turbocharger system is a complex assembly of components working in harmony to enhance vehicle performance. At its core, it consists of a turbine and a compressor. The turbine is driven by exhaust gases from the engine, which spins the compressor, drawing in ambient air and compressing it before feeding it into the engine. This forced induction results in increased air density, allowing the engine to burn more fuel and produce higher horsepower.

Key components include the turbocharger itself, an intercooler to cool the compressed air, and an aftercooler (or charge cooler) to further lower the air temperature. A crucial sensor, known as the mass flow sensor, monitors incoming air volume while performance air filters ensure clean air supply. The exhaust system, including a cat back exhaust, plays a role in spinning the turbocharger by expelling spent gases at high pressure. Understanding these interactions is vital for identifying and preventing common issues that can negatively impact vehicle performance.

Common Issues: From Oil Leaks to Sensor Malfunctions

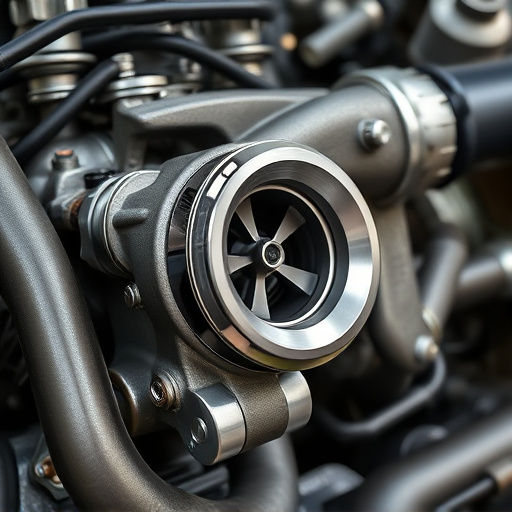

The turbocharger system, a complex mechanism designed to boost engine power, is not immune to issues that can affect its performance and longevity. Common problems range from seemingly minor leaks to more critical sensor malfunctions. Oil leaks, often stemming from worn seals or gaskets within the system, can cause significant damage if left unaddressed. These leaks not only lead to reduced engine oil levels but also pose a risk of increased friction and potential engine overheating.

Sensor malfunctions, on the other hand, are equally concerning. The turbocharger relies heavily on sensors for precise control of boost pressure, temperature, and other critical parameters. Malfunctions in these sensors can result in inefficient turbocharging, poor engine performance, and even potential damage to the turbine and compressor wheels. Regular maintenance, including inspection of intake components, timely repairs, and ensuring optimal suspension kits for smooth operation, is crucial in preventing such issues from arising or escalating.

Preventive Measures: Maintenance Tips for Reliable Performance

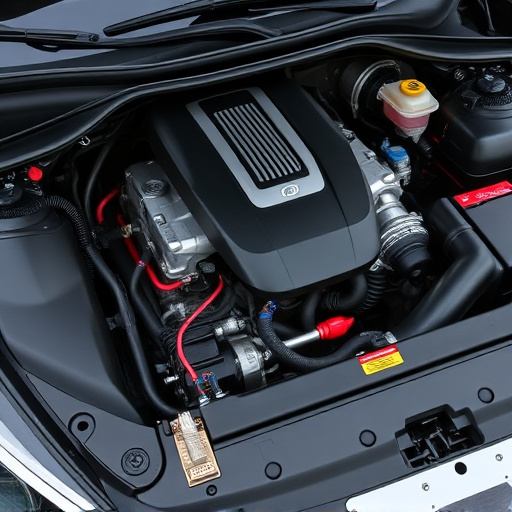

Regular maintenance is key to keeping your turbocharger system running smoothly and efficiently. One of the most important preventive measures is to ensure regular cleaning and replacement of performance air filters, as clogged or dirty filters can restrict airflow, reducing engine power and fuel efficiency. Additionally, a well-maintained cat back exhaust system contributes to optimal turbocharger performance by ensuring gases flow freely from the combustion chamber to the turbine.

Other vital tips include keeping an eye on your vehicle’s oil levels and changing it according to the manufacturer’s recommendations. Regular checks for leaks, especially around the turbocharger, are also crucial to prevent damage caused by low oil pressure. Maintaining a healthy level of engine oil ensures smooth turbine operation and protects against wear and tear, thereby extending the lifespan of your turbocharger system and enhancing overall vehicle performance.

A well-maintained turbocharger system is vital for optimal engine performance and longevity. By understanding the basic components and functions, identifying common issues like oil leaks and sensor malfunctions, and implementing preventive measures, vehicle owners can ensure their turbochargers run reliably. Regular maintenance checks and following best practices can significantly reduce the occurrence of these issues, ensuring your turbocharger system continues to enhance your driving experience.