Understanding a turbocharger system's fundamentals is key to effective cooling practices. As a forced-induction device, it enhances engine power through compressed air intake, allowing for increased fuel burn and performance. Coolant management, strategic component placement (intercoolers, water pumps), efficient exhaust systems, and clean air filters balance cooling needs for optimal turbocharger performance, longevity, and safety when modifying. Regular maintenance ensures peak functionality.

In today’s high-performance vehicles, proper turbocharger system cooling is crucial for maintaining optimal efficiency and preventing overheating. This comprehensive guide delves into the best practices for keeping your turbocharger cool. We’ll start by understanding the fundamentals of the turbocharger system and its key components, identifying the parts that contribute to efficient cooling. Next, we’ll explore maintenance tips and common mistakes to avoid, ensuring you keep your turbocharger running smoothly and effectively.

- Understanding Turbocharger System Basics for Effective Cooling

- Key Components in Achieving Optimal Cooling Efficiency

- Maintenance Tips and Common Mistakes to Avoid Overheating

Understanding Turbocharger System Basics for Effective Cooling

Understanding the fundamentals of a turbocharger system is key to effective cooling practices. A turbocharger is a forced-induction device that increases an internal combustion engine’s power output by compressing incoming air. This process involves forcing more air into the combustion chamber, allowing for larger amounts of fuel to be burned, resulting in enhanced performance and torque. The system consists of several components: the compressor, turbine, and exhaust manifold, all working in harmony. By cooling this intricate machinery efficiently, we can ensure optimal turbocharger performance and longevity.

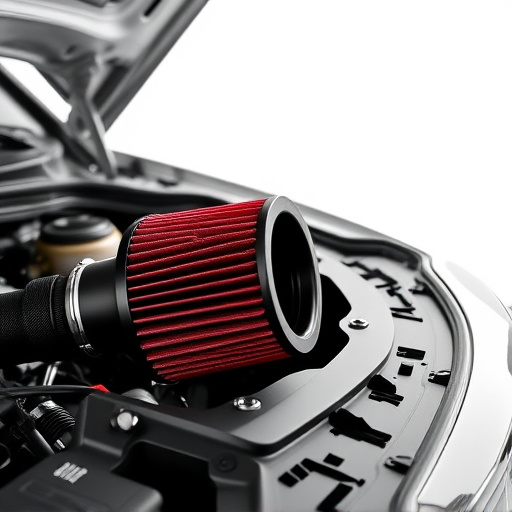

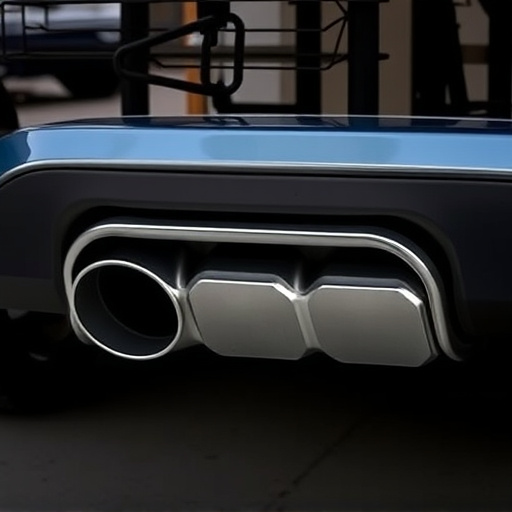

Proper cooling is crucial to prevent overheating, which can lead to severe damage. This involves managing heat dissipation through strategic placement of cooling components, such as intercoolers and water pumps. Additionally, maintaining a clean air filter kit ensures efficient airflow, enhancing the cooling process. Upgrading to high-performance exhaust tips or systems can also aid in temperature regulation by facilitating faster gas expulsion, reducing backpressure, and improving overall turbocharger efficiency.

Key Components in Achieving Optimal Cooling Efficiency

In a turbocharger system, achieving optimal cooling efficiency requires a harmonious balance between several key components. The first and foremost is the cooling fan. This component plays a pivotal role in dissipating heat by drawing in cool air from the ambient and directing it towards the hot components of the turbocharger. Efficient cooling fans are designed to provide ample airflow while minimizing power consumption, ensuring the system remains cool under heavy loads.

Complementing the cooling fan are exhaust systems and cat back exhaust configurations that facilitate effective heat transfer. These systems channel away the heated gases, allowing for a continuous supply of cooler air from the intake side. Additionally, regular maintenance of the air filter kits is crucial. Clean air filters ensure unfettered airflow, preventing any restriction that could impede cooling efficiency. By keeping these components in top shape and working cohesively, a turbocharger system can maintain optimal performance and longevity.

Maintenance Tips and Common Mistakes to Avoid Overheating

Regular maintenance is key to keeping your turbocharger system running cool and efficiently. One of the primary causes of overheating is inadequate cooling, which can be mitigated by ensuring proper fluid levels in the coolant reservoir. Check for leaks and top up as needed; a well-maintained cooling system circulates the right amount of coolant to absorb heat from the turbo. Additionally, keeping the air intake clean with performance air filters helps optimize airflow and reduces resistance, preventing excessive strain on the turbocharger.

Avoiding common mistakes is equally important. One frequent error is neglecting the muffler tips, which can become clogged or damaged over time. Regular inspection and replacement as needed ensure optimal gas flow and prevent backpressure that could overwork your turbo. Another mistake is using aftermarket coilover kits without considering their compatibility with your vehicle’s suspension. Improperly installed or incompatible coilovers may compromise cooling efficiency, leading to overheating issues. Always prioritize safety and performance by consulting professionals when modifying your turbocharger system.

Cooling a turbocharger system effectively is paramount for maintaining optimal performance, extending component lifespan, and ensuring overall efficiency. By understanding the basic principles of the turbocharger, identifying key cooling components, and adhering to regular maintenance practices, you can prevent overheating and keep your turbocharger running smoothly. Remember, proper cooling is a critical aspect of turbocharger management, directly impacting both engine power and durability in today’s high-performance vehicles.