Ball bearing turbochargers, known for their rolling element design, offer efficient air compression for optimal engine performance, immediate power delivery, and are popular in high-performance vehicles. The Journal Turbocharger System, featuring a journal bearing to support the rotating shaft, provides increased durability under extreme conditions and smoother power delivery, making it ideal for off-road or aggressive driving styles. Both systems have distinct performance characteristics: ball bearings excel at consistent speed and precision, while journal turbochargers outperform in rapid acceleration or heavy loads. Maintenance requirements differ, with ball bearings needing minimal upkeep and journal turbochargers requiring more frequent oil changes and component monitoring, emphasizing the choice based on specific performance demands and operating conditions.

In the realm of automotive performance, turbochargers have emerged as game-changers. Among them, ball bearing and journal turbochargers stand out with distinct designs and capabilities. This article delves into the fundamental principles behind these systems, exploring how each operates to enhance engine efficiency and durability. Through a detailed analysis, we compare their performance, maintenance requirements, and diverse applications, providing insights crucial for automotive enthusiasts and professionals alike, all while shedding light on the nuances of turbocharger systems.

- Understanding Ball Bearing Turbochargers: Basic Principles and Design

- Journal Turbocharger System: Unlocking Enhanced Efficiency and Durability

- Comparing Performance, Maintenance, and Applications: A Detailed Analysis

Understanding Ball Bearing Turbochargers: Basic Principles and Design

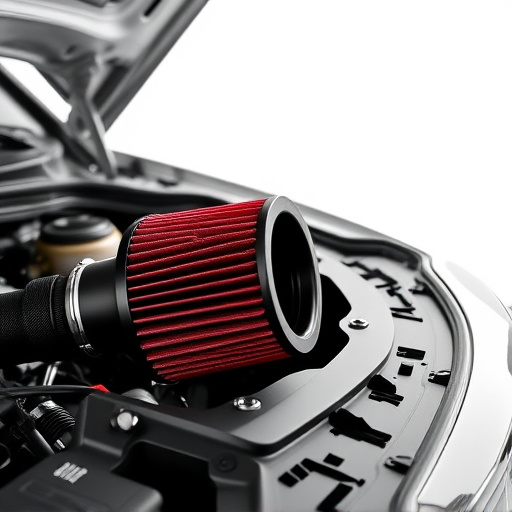

Ball bearing turbochargers operate on a simple yet powerful principle: using a system of balls bearings to reduce friction and facilitate rapid rotation. This design is integral to their efficiency, enabling them to compress and force more air into an engine’s combustion chamber. The basic structure involves a rotating wheel with pockets that house rolling elements, usually balls, allowing for smooth and fast movement. This mechanism differs significantly from traditional turbocharger designs, which often rely on fluid or mechanical energy transfer.

The ball bearing turbocharger system is strategically designed to withstand high-pressure and high-temperature conditions within an engine. Key components include a compressor housing, a rotating wheel (or impeller), the ball bearings themselves, and a shaft. Air is drawn in, compressed by the spinning wheel, and then expelled to increase engine power and torque. This direct energy transfer makes ball bearing turbochargers known for their responsiveness and ability to deliver instant power boosts, often favored in high-performance vehicles and racing applications. Moreover, proper maintenance involves regular checks of these bearings to ensure they remain lubricated and free from debris, as well as careful consideration of exhaust tips and muffler modifications to maximize performance without compromising reliability.

Journal Turbocharger System: Unlocking Enhanced Efficiency and Durability

The Journal Turbocharger System is a sophisticated mechanism designed to unlock enhanced efficiency and durability in vehicles, particularly those equipped with high-performance parts. Unlike ball bearing turbochargers that primarily rely on rolling elements for rotation, journal turbochargers utilize a unique system where a journal bearing supports the rotating shaft. This innovative design significantly reduces friction, leading to improved energy conversion and overall vehicle performance.

By minimizing wear and tear, the journal turbocharger system ensures longevity even under extreme conditions. This is particularly beneficial for off-road vehicles or those with aggressive driving styles, as it means less maintenance and greater reliability over time. Moreover, this design contributes to a smoother power delivery, enhancing the driver’s control and making high-performance parts more accessible and efficient in various suspension kits.

Comparing Performance, Maintenance, and Applications: A Detailed Analysis

When comparing ball bearing and journal turbocharger systems, a detailed analysis reveals contrasting performance profiles. Ball bearings, known for their smooth rotation and low friction, offer superior efficiency in applications requiring consistent speed and precision. They are often preferred in high-performance vehicles where minimizing wear and maintaining optimal operating conditions is paramount. Conversely, journal turbochargers excel under extreme conditions, delivering exceptional power increases in automotive settings that demand peak performance during rapid acceleration or heavy loads.

In terms of maintenance, ball bearings generally require less upkeep due to their self-lubricating nature and robust design. Regular checks for wear and timely replacements are sufficient. In contrast, journal turbochargers necessitate more meticulous care, involving frequent oil changes and closer monitoring of critical components like brake rotors and air intake systems. This is especially true in high-performance vehicles where the turbocharger system faces constant stress. Despite these differences, both types find applications in various industries, with choices ultimately hinging on specific performance needs, operating environments, and maintenance considerations.

In conclusion, both ball bearing and journal turbochargers offer unique advantages in automotive performance and efficiency. Understanding their distinct design principles, performance capabilities, and maintenance requirements is key to selecting the optimal turbocharger system for specific applications. The detailed analysis highlights how these differences impact real-world scenarios, emphasizing that each has its place in enhancing engine output while ensuring durability. By grasping these key differences, vehicle manufacturers can make informed decisions, leveraging the strengths of each type to create powerful and reliable turbocharger systems.